Yesterday I came home from school suprised to see that my brother had already installed the hardwood floor! He has a second job in flooring and got this really nice stuff for free.

Yesterday I came home from school suprised to see that my brother had already installed the hardwood floor! He has a second job in flooring and got this really nice stuff for free.

Friday, October 24, 2008

Conversion Photo Journal 3

Wednesday, October 22, 2008

The Conversion Photo Journal 2

Here are the fruits of this past weekend's labors.

Opening boxes is always exciting.

Opening boxes is always exciting.Important information!!! When you get a solar panel you need to know its output in volts and amps, all of the maximum ratings, and just about everything else in order to safely use it and also to maximize system efficiency.

Here, I'm "dry fitting" the mounting brackets...

Here, I'm "dry fitting" the mounting brackets... ...and measuring to make sure everything will fit on the roof.

...and measuring to make sure everything will fit on the roof. Once the measurements were made and everything was how I wanted it, I marked where the mounting brackets needed to be attached to the panels.

Once the measurements were made and everything was how I wanted it, I marked where the mounting brackets needed to be attached to the panels. Then, I flipped the panels over and started wiring everything up. They needed to be wired before mounting because I wouldn't be able to reach under and wire it up once the panels were right side up.

Then, I flipped the panels over and started wiring everything up. They needed to be wired before mounting because I wouldn't be able to reach under and wire it up once the panels were right side up.

Panels wired together in parallel.

Panels wired together in parallel.

I used tamper-resistant bolts that require a special star Allen wrench.

With the tamper resistant bolts, I used a few tamper resistant nuts. The top part breaks off once it is torqued enough and leaves an un-wrench-able smooth surface. This way no one can steal my panels!

Once all the mounting brackets were attached, I covered the panels in the foam they were packaged in and wrapped them up in bubble wrap just in case they were to slip while I was trying to get them up on the roof. Here I used a blanket to help me slide the panels up without scratching up my van.

On top! Unfortunately the mounting brackets scratched the roof up a lot. It's not that big of a deal though because no one can see the roof and it is made out of fiberglass so it won't rust.

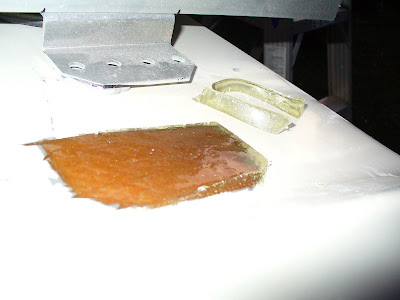

I used putty to hold the panels in place while preparing the roof for mounting. The roof is curved and not level, but the panels are ridged and the mounts require a level surface. My solution: fiberglass roof extensions. I stripped the areas where the mounts would go and then made moulds and poured in more fiberglass resin to give a level surface.

Before I could pour the resin, I wanted to make sure that the van was level so that the new mounting surface would be even. First, I parked the van as level as I could get it.

Then I used a lot of heavy crap to get the van perfectly level.

Then I measured, mixed, and poured fiberglass. Here is the first one I did. The fiberglass resin filled the mould, bonded to the roof and leveled the surface perfectly.

This was the only one I got done before it was too dark to do any more. So I went into the garage and started work on my kitchen.

Cutting wood the old fashioned way.

Kitchen: I put the sink and stove top in just to show off how it will look. It's still far from done.

So that's all I got done last weekend. Today I finished bolting the panels to the roof, now I just have to wire them up to the charge controller and batteries. Thursday my brother is bringing over the hardwood flooring and is going to help me install it. I'm trying to get as much done as I can before it starts getting really cold outside. Once the floor is done I can start insulating the walls and getting the wiring in place and hook up all of the kitchen stuff. I'm estimating all of that will take about 2 more weeks.

Monday, October 20, 2008

An Overview of Solar Power

Saturday, October 11, 2008

Conversion Photo Journal 1

I took out all of the back seats in a day. They were bolted through the floor and then the foam and carpet were installed on top of that. So I had to tear out the carpet and foam before I could get to the bolts. You can also faintly see the rear AC unit in the back that I had disconnected. The two captains chairs were heavy! They weighed about 60lbs each. The back chair was no lightweight either. The whole van will probably the same after I'm done turning it into a home.

I took out all of the back seats in a day. They were bolted through the floor and then the foam and carpet were installed on top of that. So I had to tear out the carpet and foam before I could get to the bolts. You can also faintly see the rear AC unit in the back that I had disconnected. The two captains chairs were heavy! They weighed about 60lbs each. The back chair was no lightweight either. The whole van will probably the same after I'm done turning it into a home.

View from the rear.

View from the rear.

Clean. All of the floor, walls and ceiling have been stripped. That ugly yellow stuff is adhesive that they used to glue the carpet to the wheel wells. I couldn't scrape it off without also removing the paint. You can also see three large holes in the floor from the previous conversion. I took out all of the upholstered stuff because it was filled with cheap nasty rotting foam.

Clean. All of the floor, walls and ceiling have been stripped. That ugly yellow stuff is adhesive that they used to glue the carpet to the wheel wells. I couldn't scrape it off without also removing the paint. You can also see three large holes in the floor from the previous conversion. I took out all of the upholstered stuff because it was filled with cheap nasty rotting foam.

The screws that hold the top to the body were rusting so I sealed them. It's not pretty but it serves a purpose and I'll make it prettier later.

The screws that hold the top to the body were rusting so I sealed them. It's not pretty but it serves a purpose and I'll make it prettier later.

I covered and sealed the large holes in the floor with aluminum flashing. Then I cut some of the better 1/4 inch plywood that I salvaged into rough strips to even out the ridges in the floor so that I would have a level surface to put the sub floor on. And then I glued it down. Say hello to my little friend... That is one hell of a caulking device.

Say hello to my little friend... That is one hell of a caulking device.  I was working well into the night with a halogen work light. Here is a picture of the various levels of my sub floor. On the bottom is the van body w/plywood strips, then there is 1/2 inch of insulating foam and then there is 1/4 inch of plywood. The foam helps insulate the van and also dampens the vibrations when walking around inside.

I was working well into the night with a halogen work light. Here is a picture of the various levels of my sub floor. On the bottom is the van body w/plywood strips, then there is 1/2 inch of insulating foam and then there is 1/4 inch of plywood. The foam helps insulate the van and also dampens the vibrations when walking around inside.

My finished sub-floor!

My finished sub-floor!

That's all for now. What's coming next? Well, on top of this beutifuly built sub-floor I'm going to install the hardwood flooring that my brother was kind enough to acquire for me. Then I'm going to build my kitchen counter and cabinets and install my solar panels. I'll probably devote an entire entry about solar panel workings and how to install and wire them correctly. It's going to be interesting stuff!

That's all for now. What's coming next? Well, on top of this beutifuly built sub-floor I'm going to install the hardwood flooring that my brother was kind enough to acquire for me. Then I'm going to build my kitchen counter and cabinets and install my solar panels. I'll probably devote an entire entry about solar panel workings and how to install and wire them correctly. It's going to be interesting stuff!